Description

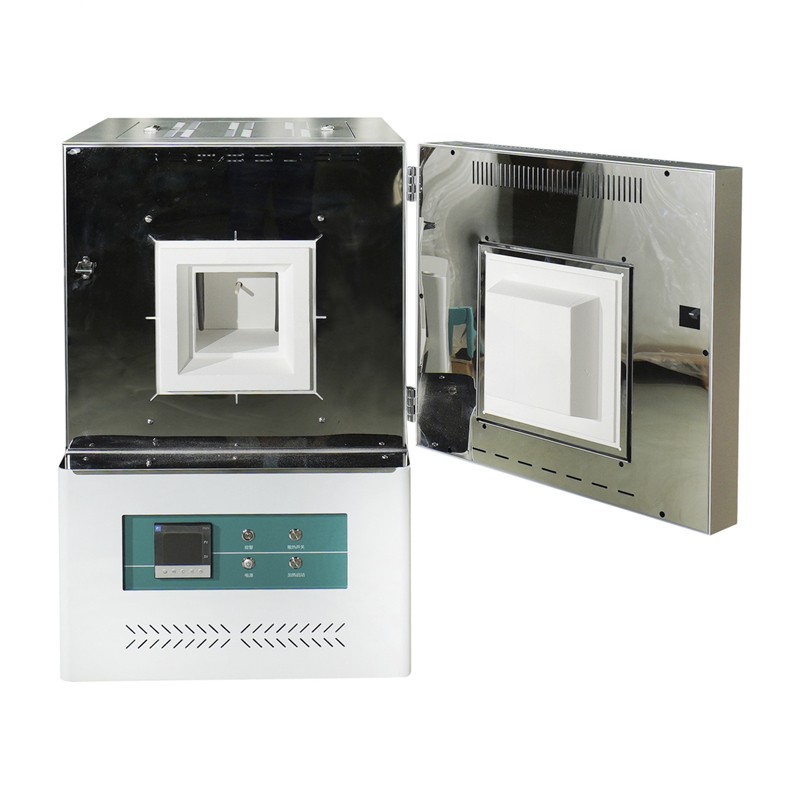

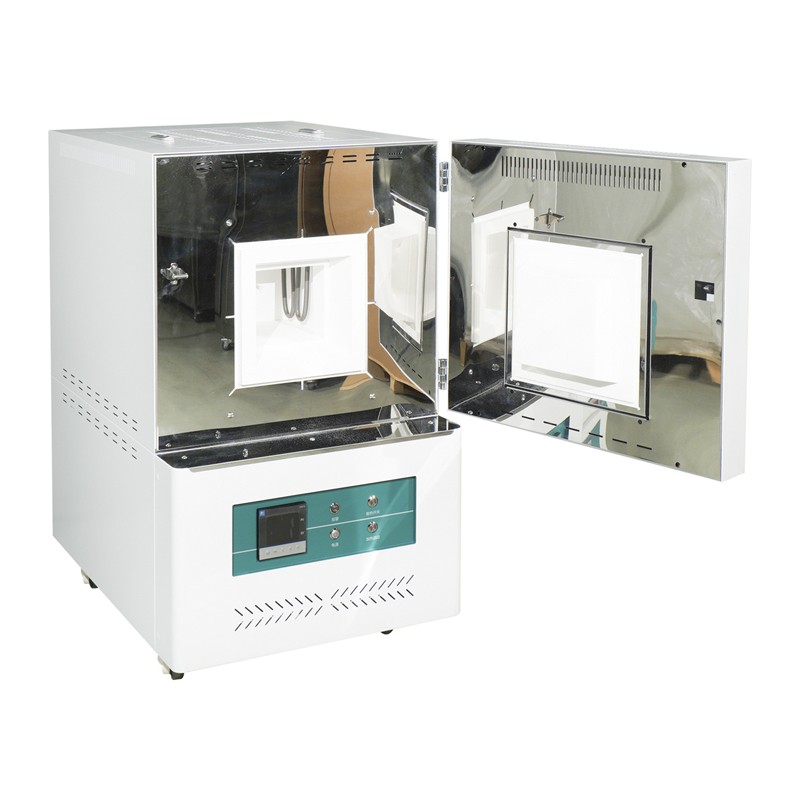

1600℃ Ceramic Fiber Muffle Furnace

1, Production introduction

It is used for sintering, melting and analyzing metal, nonmetal and other compound materials in laboratories of universities, research institutes and industrial and mining enterprises.

2, Features

1. Mirror stainless steel furnace mouth, long-term use will not change color.

2. Vacuum-forming polycrystalline mullite fiber furnace, high efficiency insulation.

3. Double shell, the air sleeve heat insulation, and double air guiding passage .

4. High-purity silicon-molybdenum rod heating, and with standard exhaust chimney.

5. High precision program controller, with imported sensor and imported voltage regulating module.

6. With leakage protection, thermocouple failure, door opening electrical outage, over-temperature protection and sound-light alarm safety device.

7. Lockable handle, quick detachable structure,easy to maintenance and repair.

8.Insulated gloves and crucible tongs are standard.

3, Specification

| Model |

30 segment Domesticc controller |

SX4-2-16 | SX4-4-16 | SX4-8-16 | SX4-12-16 | SX4-20-16 | SX4-36-16 |

|

64 Segment Import Controller (Model With P) |

SX4-2-16P | SX4-4-16P | SX4-8-16P | SX4-12-16P | SX4-20-16P | SX4-36-16P | |

|

30 Segment 7.0 Inch Touch Screen controller (Model With PL) |

SX4-2-16PL | SX4-4-16PL | SX4-8-16PL | SX4-12-16PL | SX4-20-16PL | SX4-36-16PL | |

| Function | Temp. Range | Max 1600℃(Long-TERM Max Continuous Service Temperature 1500℃) | |||||

| Temp. Accuracy | ±1℃ | ||||||

| Temp. Resolution Ratio | 1℃ | ||||||

| Temp.RISING Time To Max Temp | <40min | ||||||

| Structure | Furnace Body | Polycrystalline Mullite Fiber | |||||

| Outer Shell | Cold rolling steel with electrostatic Spraying exterior | ||||||

| Chamber Size | 150*90*150 | 150*150*150 | 300*150*150 | 300*200*200 | 300*260*260 | 300*400*300 | |

| Exhaust Hole | Diφ22,Deφ18 | ||||||

| Heater | Sillcon Molybdenum Rod | ||||||

| Heating Power | 3KW | 5.5KW | 9KW | 10KW | 12KW | 15KW | |

| Controller | Temp.Control | No Letter Model : LED Programmed Controller; | |||||

| P Type: LCD Imported Programmed Controller ; | |||||||

| PL Type: 7.0-inch touch screen program controller, with curve viewing and USB data storage functions. | |||||||

| Termp. Control Mode | Intelligent Microcomputer PID Control | ||||||

| Display Mode | No Letter Model:4 keysSettings P Type:5 keys Settings PL Type:Touch Type Operation | ||||||

| Timer | No Letter Model:0-9999min P Type:0-99hour59min PL Type:0-9999min | ||||||

| Operation Function | Constant Value Operation Or Program Operation | ||||||

| Sensor | S-type Thermocouple | ||||||

| Additional Function | Heating Start Stop Button, Sensor Fault Alarm,Temperature Overshoot Self Setting,Temperature Correction | ||||||

| Safety Device | Overtemperature Alarm, Leakage Protection, Door Opening Heating | ||||||

| Specification | Exterior Size (W*L*H)(mm) | 600*755*1100 | 600*815*1100 | 750*815*1100 | 750*865*1150 | 750*925*1210 | 750*1065*1250 |

| Packing Size (W*L*H)(mm) | 760*925*1310 | 760*985*1310 | 910*985*1310 | 910*1045*1360 | 910*1105*1420 | 910*1265*1460 | |

| Volume | 2L | 4L | 8L | 12L | 20L | 36L | |

| Curent Rating (50/60HZ) | AC220V 50Hz | AC380V 50Hz | |||||

| NW/GW (kg ) | 70/90 | 80/100 | 110/130 | 150/170 | 175/195 | 270/320 | |